Optimising electron microscope performance via continuous environmental monitoring

The unparalleled magnification capabilities of electron microscopes (EMs) make them indispensable for applications requiring nanometre scale imaging. However, the sensitivity required to operate at such high magnification levels leaves them vulnerable to magnetic field perturbations, vibration and changes in temperature and humidity, all of which need to be kept to a minimum to ensure peak performance. Keeping track of such environmental factors is no mean feat, but dedicated continuous monitoring systems are now available to detect changes in instrument surroundings in real time, simplifying troubleshooting procedures and ensuring optimal device performance.

Blurred lines

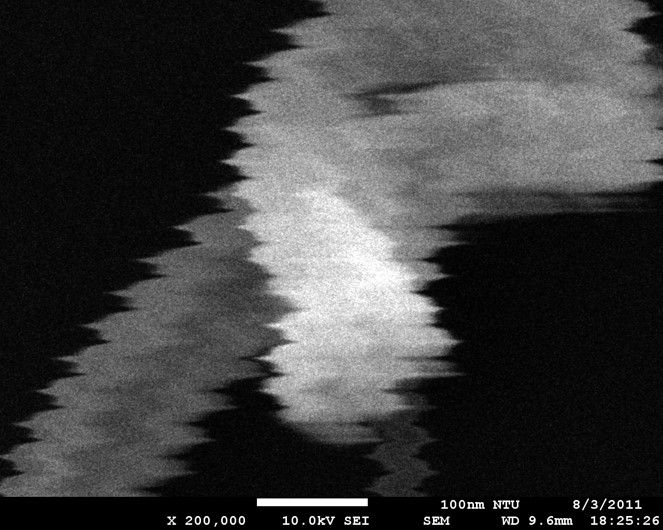

The superior magnification offered by EMs stems from the use of electrons instead of light to probe a sample; the wavelength of these particles can be many orders of magnitude shorter than photons on the visible spectrum, enabling them to resolve much smaller features. The beam of electrons is focused on the specimen, and interacts with atoms in the sample to produce signals that contain information about surface topography and composition. Seeing details at such a small scale requires the beam to be perfectly positioned and focused, which can be compromised by external interferences from acoustic noise and vibrations, leading to blurred images. Additionally, since the electrons are charged particles, EM performance is also greatly affected by external magnetic fields. This leads to distinct artefacts appearing in the image; AC fields often show up as sharp jagged edges, while DC fields create wavy lines. EM manufacturers therefore precisely map and specify the degree of interference that their instruments can handle before the image quality drops below the acceptable limit.

Surveying the problem

Optimal EM performance relies on careful monitoring of the surroundings, both before and after device installation. Purpose-made survey systems can be used to evaluate if a room is suitable to host such sensitive equipment, identifying vibrations and noise – for example, from nearby traffic or elevators – as well as magnetic fields that come from surrounding equipment or other less obvious sources, like heating or air conditioning systems. It is just as important to check for these perturbations once installation is complete, particularly for applications such as the quality control and failure analysis process of semiconductor manufacturing, where even small interferences can affect EM performance and make it difficult to identify product defects. However, until recently, there was no technology available on the market that would allow uninterrupted, long term monitoring of magnetic fields, sounds, vibrations, temperature and humidity, meaning few EM users had access to the relevant environmental data when an issue with imaging performance arose.

Continuous environmental monitoring

Delays caused by blurry or distorted images can cost users precious time – potentially halting the progress of research or decreasing manufacturing productivity – making it crucial to resolve imaging issues quickly and efficiently. Unfortunately, pinpointing the root cause of poor image quality can be a lengthy process. When something is wrong with an EM image, it can be hard to discern if the issue is internal – originating from faulty instrument components – or if some external disturbances are affecting electron beam focusing. For most EM users, the first point of contact to resolve performance issues will be their EM manufacturer or service organisation, who will send an engineer to investigate the problem. However, if no obvious fault can be found with the instrument, the manufacturer will then reach out to a magnetic field expert, as well as vibration and acoustic protection suppliers, to help them diagnose what is wrong, which results in a lengthy process and multiple site visits.

Continuous environmental monitoring offers a convenient solution to help eliminate this protracted diagnostic process. If a problem with EM performance occurs, users can quickly and easily review the magnetic field, acoustic, vibration, temperature and humidity data – organised into date-stamped files and viewed using bespoke software – from the time of image quality loss, immediately identifying if the problem is the result of an issue with the instrument itself or an external factor. This data can even be supplied to relevant external parties – equipment manufacturers or service organisations – to allow more effective diagnosis of instrument problems without visiting the site, significantly reducing the downtime and ensuring any necessary on-site interventions are as efficient as possible.

Environmental monitoring can also provide an early warning system if parameters exceed user-defined limits, minimising the chance of unnecessary downtime for EMs used in semiconductor inspection. This warning system can be either visual – a traffic light tool that is green when the environmental parameters are within the user-specified range, and turns red when an issue is spotted – or electronic, sending an email notification to the user with a short summary of the situation. This technology will also be of great value for EM manufacturers during the production of electron microscopes, as they can easily check whether issues with their instruments are caused by hardware problems or perturbations in the surroundings, something that can be equally useful during instrument assembly.

Bringing EMs into focus

Blurry or distorted EM images can cause a variety of issues for researchers and engineers alike, making it crucial to be able to quickly determine the root cause of these problems. Fortunately, EM users now have access to a dedicated environmental monitoring solution that can help pinpoint whether an issue is caused by internal factors, or is a result of external interferences. The new SC28 monitoring system (Spicer Consulting) can track magnetic fields, acoustic noise and vibrations – as well as temperature and humidity – to provide EM users with the environmental data essential for timely and efficient diagnosis of imaging performance issues. This system can even notify the user when these parameters are beyond the allowed limits, saving precious time and giving EM operators full confidence that their instruments are operating under appropriate conditions.

Click here for more information about the SC28 monitoring system

About Spicer Consulting Limited

Spicer Consulting magnetic field cancelling systems protect electron beam instruments – including scanning electron microscopes (SEM), transmission electron microscopes (TEM), electron beam lithography tools and SEM-based metrology and inspection tools – in the world's leading laboratories, universities and semiconductor manufacturing plants, as well as in the test facilities of electron and ion beam equipment manufacturers. Its magnetic field, vibration and acoustic analysis systems have been adopted as standard equipment for conducting site surveys by leading equipment manufacturers. Spicer Consulting is located in Stewartby, Bedfordshire, within the United Kingdom’s golden triangle of elite universities in London, Cambridge and Oxford.

Spicer Consulting Limited, Eden Laboratory, Broadmead Road, Stewartby, Bedfordshire MK43 9ND, England

TEL:+44(0)1234 765773

Email: enq@spicerconsulting.com

© 2023 Spicer Consulting Limited.

All rights reserved. Privacy Notice.

Contact Us

We will get back to you as soon as possible.

Please try again later.